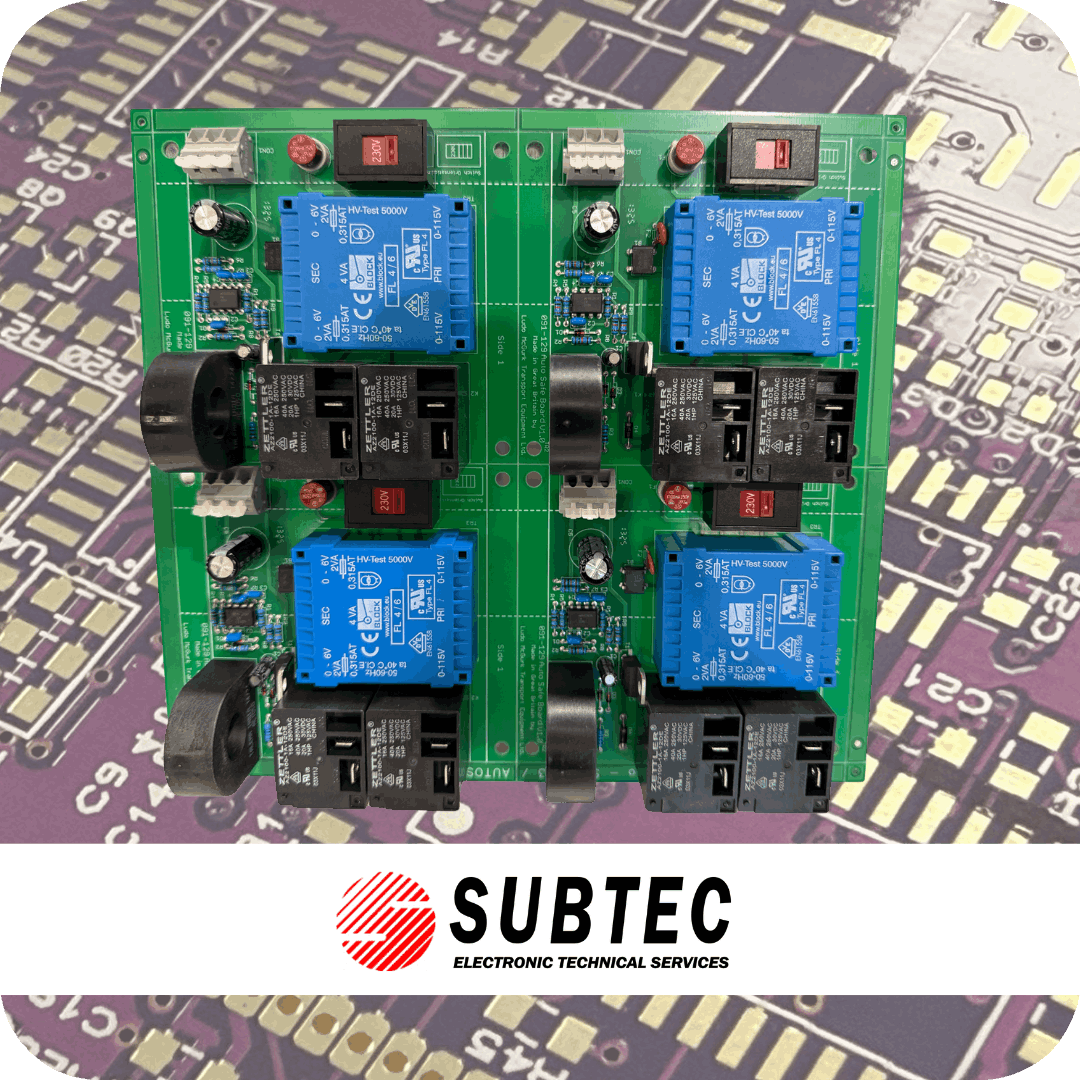

PCB Prototyping & Design

With a very strong knowledge of the production process, we are often called upon by our clients to assist with a wide variety of PCB Prototyping services. Our expertise means that we can get involved with the initial design concept of a prototype PCB assembly, ensuring a production friendly final design.

With a wide range of skills ourselves, and long standing contacts with experts in many areas, we are able the to develop not only the PCB prototype assembly, but other required skills such as metalwork and machining for point of sale products.

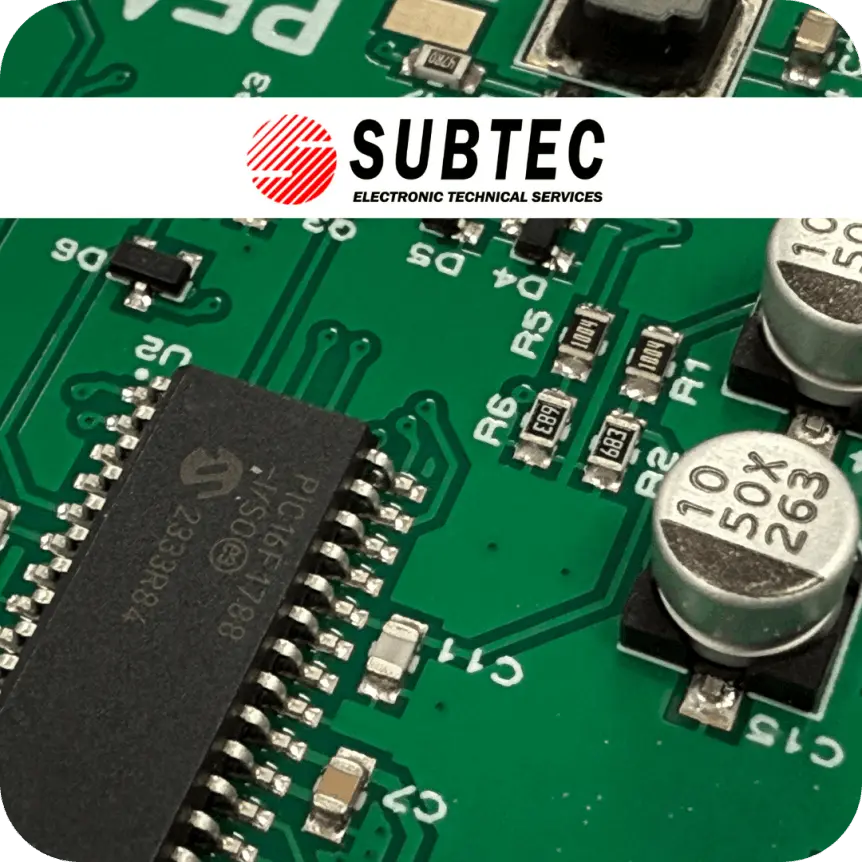

Why Use SUBTEC for PCB Prototyping?

> From PCB design to assembly of the Prototype, deal with just one company – giving you consistency in approach.

> All components & PCB’s sourced by Subtec or free issue, helping keep costs down.